‘Behind the Scenes: Creating Echoes of Glory’

This is how a Legacy Piece comes to life - from concept to creation

What goes into a Legacy Piece? This is the complete journey of creating 'Echoes of Glory' - from first conversation to bronze sculpture. See why collectors wait months for work like this.

Step 1. From Story to Concept.

It all started with a conversation.

During our Visual Taste Test interview, key themes emerged: a deep love for ancient Greek art, the power of bronze as a medium, and how the equestrian lifestyle shapes every aspect of daily life.

Within minutes of our conversation, I had a complete vision:

A 3D sculptural portrait crafted from precision bronze wireframe, with fragments of meaningful moments captured between the lines - creating a living memory that shifts with perspective.

The goal: *'to capture the feeling of being in motion, the elements you notice, the pure joy of connection, and the beautiful bond between human and nature'.*

Material exploration included: **Fine art prints on translucent acrylic • precision bronze wireframe • authentic textural elements**

People told me this concept was impossible with thin bronze lines. "It would never work," they said. But I saw it in my mind. So I knew it could work.

I used AI visualization to create initial concept sketches - helping translate the vision from imagination into something tangible that everyone could understand and build upon.

Step 2. testing materials.

I created physical prototypes using acrylic glass shapes, test prints, and brass wire to make the concept tangible. This hands-on experimentation phase is crucial - it's where theory meets reality and potential problems reveal themselves before production begins.

Acrylic graphic shapes, combined to make a 3D collage.

Prints of the equestrian fragments.

Cut outs of the prints I used.

The first try out, with fragmented memories on acrylic glass, and bronze lines.

I'm a visual thinker, so I made a test to see how my idea corresponded with real life.

In the actual piece I will first make a complete frame out of bronze and afterwards add the slides with the fragments of memories, but this is a good start into the creation process.

Elements used in this test:

- Natural textures and environments

- Lighting at different times of day

- Seasonal details (autumn leaves, grass, bark)

- Personal artifacts meaningful to the story

- Architectural elements from significant places

- Organic materials that capture essence and memory

This prototype phase reveals how light, texture, and memory interact within the sculptural framework.

Step 3: Scale and Technical Planning

Creating a life-size bronze sculpture requires extensive anatomical research and precise dimensional planning.

I study the subject's proportions, research breed-specific characteristics, and calculate optimal dimensions for both accuracy and visual impact.

Key considerations include:

- Anatomical proportions and natural stance

- Viewing angles and display requirements

- Structural integrity for the chosen materials

- Pedestal height for optimal experience

This technical foundation ensures the final sculpture captures both biological authenticity and artistic presence.

The planning phase typically involves detailed measurements, structural calculations, and material stress testing before production begins.

For research I went to the Living Horse Museum. A beautiful place with a lot of history and inspiration.

I also had the chance to meet with André Marques Alcantara, a professional horse rider from Portugal. He shared his deep love for riding and what it means to him—it was incredibly insightful!

André also gave me some interesting tips, like using a GoPro camera mounted on the chest or head to record riding sessions. This might be a cool way to capture the surroundings and movement.

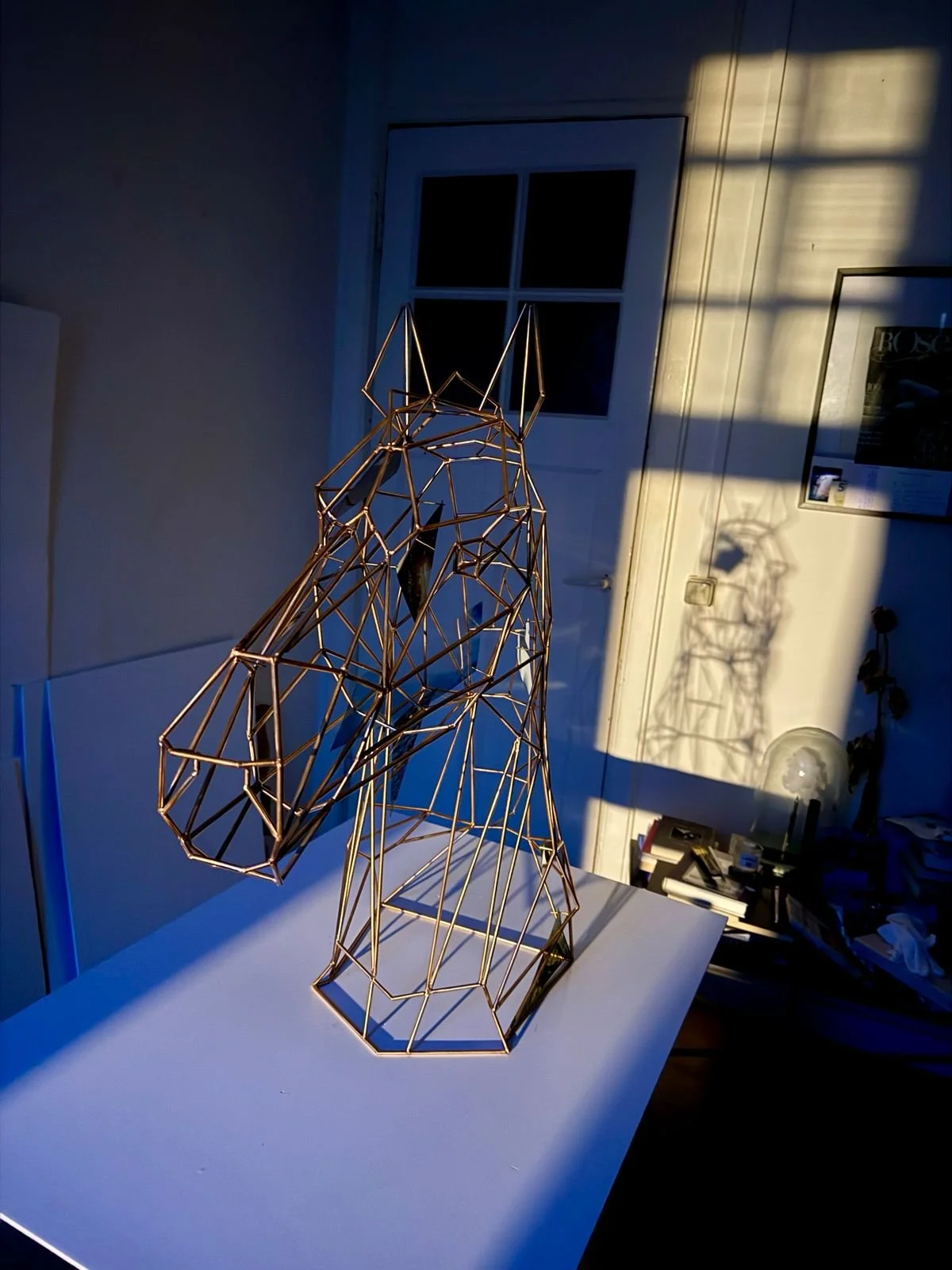

I made a 3D model out of the horses head, as a tool to explain to the technical designer what I need for the calculation of the object.

*Side note: I made this drawing, without the real horse hair. This will - of course -be a part of the final piece.

The Final Technical drawing for the frame.

To Bronze or to Brass, that is the question.

Material options:

Patinated brass

Brass is an alloy of copper and zinc. The zinc content can vary, typically between 5% and 40%.

Material options:

Patinated bronze

Bronze is an alloy of copper and tin, although it may also contain small amounts of other metals like aluminum, phosphorus, or silicon.

So here’s an example of how the company that’s going to assemble the frame bronzes brass. ↙️

(not breaking) the mold

But definitely a lot of finetuning! After many adapted versions, I could finally add the finishing touches on the mold for the bronze design.

Picking up the bronze

Planes, trains and automobiles. It was a journey, but the bronze is in!

Cutting 280 bronze rods.

The first weld being made

Welding bronze is not for the faint of heart. It took me a good deal of digging and then I found a bronze caster in the east of The Netherlands, upon referral.

But the intricate wireframe design proved more challenging than expected. The precision required for 280, individual 4mm bronze rods demanded specialized computer-steered welding techniques.

In comes blacksmith Cuiper, to save the day!

Coincidentally my bronze supplier came over to Amsterdam to personally deliver some extra bronze rods. I showed him what was happening with the bronze caster and gave me the phone number of a specialized blacksmith, that can work with special metals.

Next day I met up with Blacksmith Cuiper, who uses a computer steered welding technique, which requires less heat, so the welds are controlled and perfect.

Happy days. The first part is in. Finally the result I'm looking for! So happy. ETA: April 12 2025

With this project, everything took its sweet time, but here the last welds where being made.

I decided to skip the real horse hair, so here we made the hair out bronze, as well.

Picking up the prints at Gallery Color. Right then and there, we had an idea: what if we would laminate the fragile prints, instead of placing them in acrylic glass. 💡

About 5 reprints/attemps to achieve the perfect lamination - wasn’t easy, but we made it work!

Moved the project to my house.

Working morning, day and night to get the job done.

Drilling the last hole.